SERVICES

OUR SERVICES

Extrusion-Link are dedicated to providing continuous support to our customers, from the initial enquiry to delivery of a project. We also recognise that aftermarket service is fundamental to the continuous production of high-quality products, and so we offer service contracts as well as remote support and upgrades during the lifetime of your extruder. Extrusion-Link doesn't just sell equipment, we are there whenever you need us.

REPAIR AND

OVERHAUL

Extrusion-Link's team specializes in rebuilding twin-screw extruders and process equipment from OEM's, delivering cost-effective solutions without compromising on quality.

Extrusion-Link specializes in rebuilding machinery including:

-

Extruders

-

Gearboxes

-

Control panels

-

Coating systems

-

Drying systems

From a range of manufacturers such as:

-

Clextral

-

Baker Perkins

-

Buhler

-

KMG

-

Lalesse

-

Christy Turner

Rebuilt machinery provides like-new performance and reliability. With shorter lead times than new equipment, you can enhance your production capabilities sooner and more cost-effectively.

INSTALLATION

Extrusion-Link have extensive international experience installing machinery for a diverse range of processing applications and can ensure a seamless integration of your new equipment.

The Extrusion-Link Advantage:

-

Engineers involved from design through installation

-

Hands-on equipment familiarization

-

Equipment positioning and setup

-

Process establishment support

-

Expert technical guidance

Our engineers work closely with your team throughout the installation process, providing training and support to ensure you're confident with your new equipment from day one.

PROCESS AND

PRODUCT

COMMISSIONING

Our comprehensive knowledge spans both electrical and mechanical aspects of extrusion equipment, combined with expertise in raw material selection and processing. This integrated approach ensures optimal performance from the get go.

Process Optimization Services:

-

Equipment commissioning

-

Production line optimization

-

Raw material consultation

-

Quality control implementation

-

Output maximization

-

Product consistency improvement

-

New product development

-

Process troubleshooting

From enhancing existing operations to developing revolutionary new products, our team provides the technical expertise and industry insight you need to succeed.

Whether you're looking to increase production output, improve product consistency, or develop entirely new product lines, our experienced team is ready to support your goals.

SERVICING

CONTRACTS

Regular and effective maintenance is essential. It ensures that:

-

Machinery is always safe and efficient

-

Consistent product is made all day, every day

-

Costs are kept low as breakdowns and stoppages are eliminated

-

Producers can comply with ISO maintenance programs and assure their customers guaranteed production

It is often difficult to maintain the expertise to do this in house, to fill this gap Extrusion-Link offers a complete service package tailored to suit each customer’s individual needs.

Our package can include:

-

Gearbox and motor inspection and mini service (typically every 6 months)

-

Gearbox full service (once every 2 years)

-

Spare sets of screws and shafts

-

Intermediate and discharge Barrels/liners

-

Overall extruder health check (typically every 6 months)

-

Fully trained engineer provided by Extrusion-Link to visit site on pre-booked dates

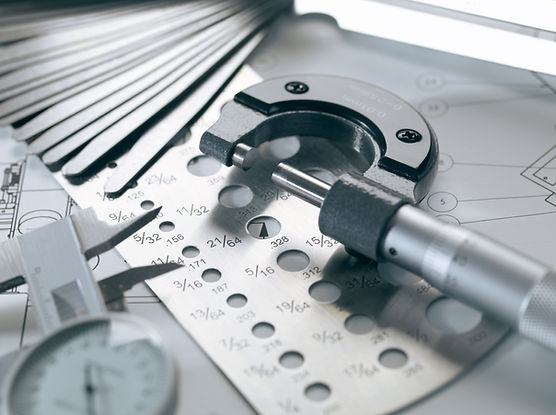

DESIGN

At Extrusion-Link, we deliver design services that form the foundation of every successful food manufacturing project. From custom die designs to complete factory layouts, our engineering expertise ensures optimal performance and efficiency.

Design Services Include:

-

Detailed factory layout planning

-

Custom die design and optimization

-

Reverse engineering of existing equipment

-

Concept design development

Our experienced engineers provide professional reverse engineering services, travelling directly to your facility to create detailed drawings of your existing machinery.

Our design process goes beyond precise measurements. We carefully consider material properties, manufacturing limitations, and process requirements to ensure every component delivers maximum performance and longevity. This attention to detail guarantees that your equipment operates at peak efficiency while maintaining product quality.

REMOTE

SUPPORT

Experience next-generation support with our advanced control systems featuring real-time monitoring and cloud connectivity. At Extrusion-Link, we keep your operations running smoothly with instant access to expert assistance.

Smart Features:

-

Real-time system monitoring

-

Instant fault detection

-

Cloud-based data storage

-

Remote troubleshooting

-

Immediate technical support

-

Historical performance tracking

Join the smart manufacturing revolution with our cloud-connected control systems. Experience the confidence that comes with having immediate access to expert support and comprehensive performance data.

TRAINING

Unlock the full potential of your extrusion equipment with our professional training programs by empowering your employees with the knowledge of how best to run your factory line. At Extrusion-Link, we prioritize operator safety and production efficiency through comprehensive hands-on training.

Our Training Solutions Cover:

-

Safety protocols and best practices

-

Equipment maintenance procedures

-

Process optimization strategies

-

Troubleshooting skills

Whether you're operating our equipment or working with existing installations, our experienced trainers provide the knowledge and skills your team needs to excel.

Training Available For:

-

Single-screw extruders

-

Twin-screw extruders

-

Existing production lines

-

Multiple operator skill levels

-

New equipment installations